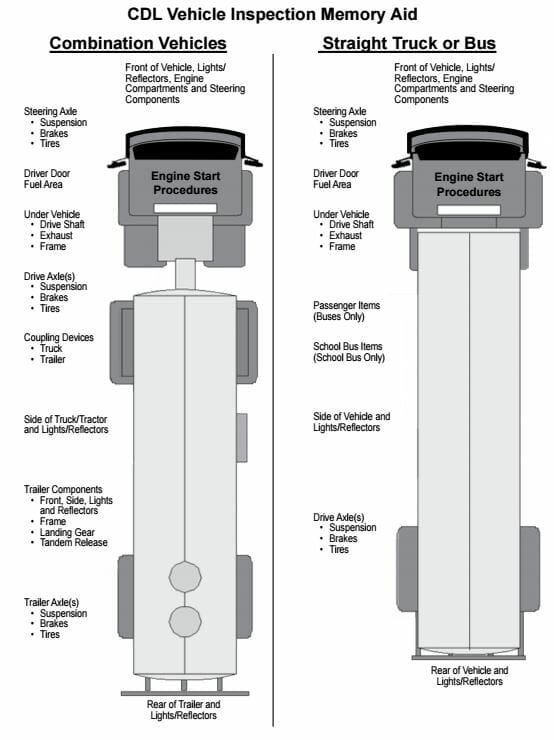

Due to heavy memorization, the pre-trip inspection is one of the hardest aspects of the CDL test. Also called the “Vehicle Inspection Test,” the pre-trip is one of the tests that trucking students fail the most.

With this pre-trip inspection checklist, we tell you everything you need to know and what you need to check for.

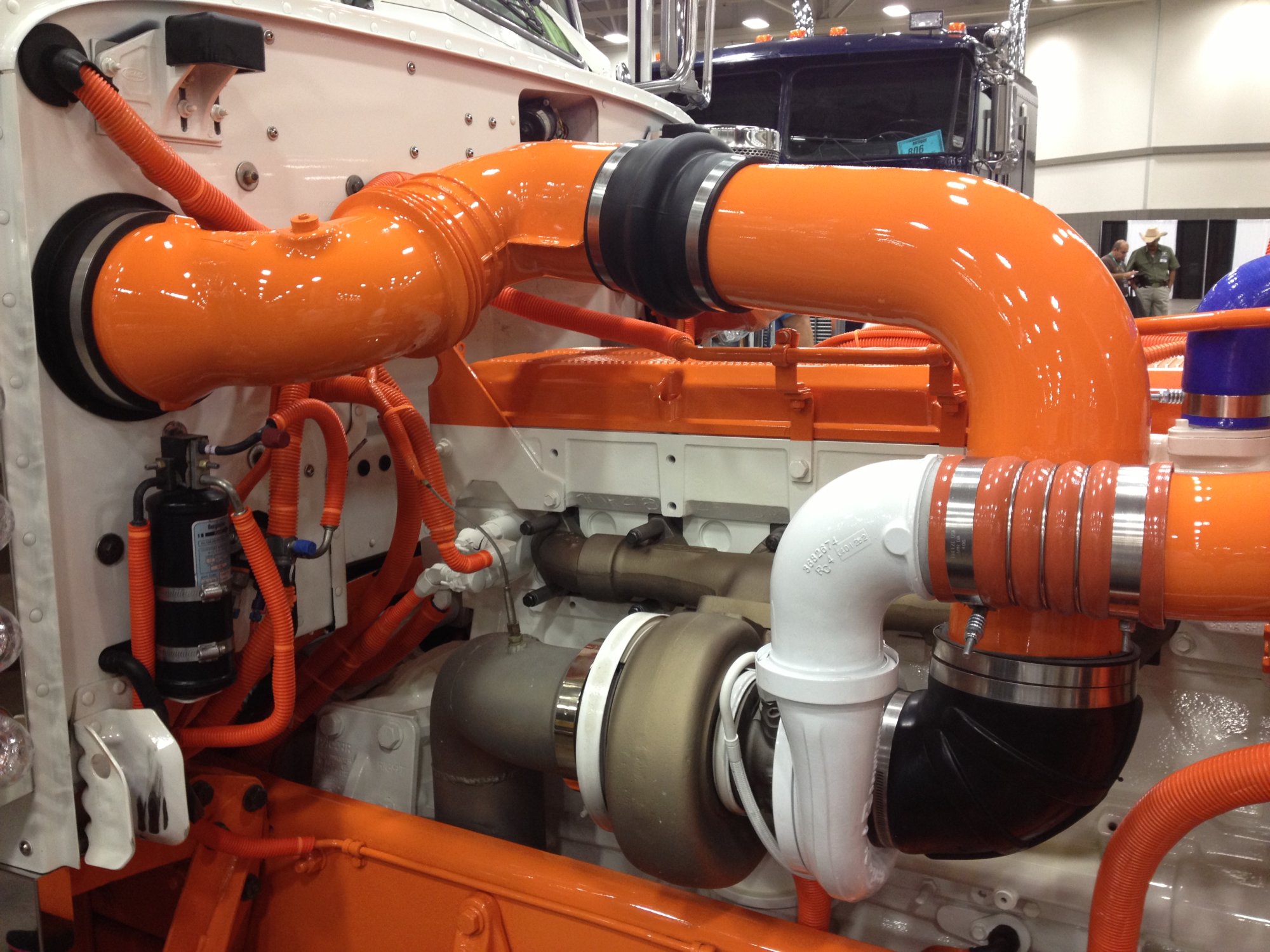

Engine Compartment – What to Check For:

When checking the engine compartment, you always want to make sure the following components are properly mounted and secured. You should also make sure they are not cracked, bent, or broken. The items you need to check for include:

Belt-Driven Alternator

All of the wires are connected. The belt is not cracked or frayed, and the free play on the belt is between ½ to ¾ of an inch.

Belt-Driven Water Pump

The free play on the belt is between ½ to ¾ of an inch, and all the hoses running to and from the water pump are tightly clamped. Ensure nothing is leaking.

Brake Chamber

The brake chamber is not leaking air.

Brake Drum

The brake drum is properly mounted and secure.

Brake Hose

The brake hose is rubber; it is not cracked and is not leaking air.

Brake Lining

Check for oil or debris on the lining. There should be at least ¼ of an inch of friction material.

Caste Nuts and Cotter Pins

All three caste nuts and cotter pins are present.

Coolant Reservoir

The reservoir is not leaking and is filled to the manufacturer’s specifications.

Drag Link

The drag link is properly mounted and secure, and not cracked, bent or broken.

Gear Box and Hoses

The gear box and hoses have no abrasions, bulges or cuts, and are not leaking.

Gear-Driven Air Compressor

The air compressor is properly mounted and does not leak.

Gear-Driven Power Steering Pump

The steering pump is properly mounted and not leaking.

General Hoses (Passenger and Driver’s Side)

The hoses are secure at both ends and are not leaking. There are no abrasions, bulges, or cuts.

Hub Seal

The hub seal (or axle seal) is leaking and is filled to the manufacturer’s specifications.

Leaf Springs

None of the leaf springs have shifted or are bent or broken.

Leaks

There are no signs of leaks under the truck.

Lug Nuts

There are no lug nuts missing. There are no rust trails, powder residue, or cracks around the bolt holes.

Oil Level

The oil level is filled to the manufacturer’s specifications.

Pitman Arm

The pitman arm is properly mounted and secure. It is not cracked, bent, or broken.

Power Steering Fluid Reservoir

The power steering reservoir is not leaking and is filled to the manufacturer’s specifications.

Rim

The rim does not have any unauthorized welds.

Shock Absorber

The shock absorber is not leaking. If it is leaking, the leak will be at the point where the top and bottom portion of the shock meet.

Slack Adjuster and Push Rod

With the brakes released and pulled by hand, the push rod does not move more than one inch.

Spring Hanger

The spring hanger is properly mounted and secure.

Steering Column

The steering column is properly mounted and secure. It is not cracked, bent, or broken.

Steer Tire

There are no abrasions, bulges, or cuts on the tread or sidewalls. Tread depth should have a depth no less than 4/32 of an inch. Tires are properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

Tie Rod

The tie rod is properly mounted and secure, not cracked, bent, or broken.

U-Bolts

Make sure all are accounted for.

Driver Door Fuel Area-What to Check For:

Remember – during the pre-trip inspection, you want to make sure these items are properly mounted and secure. Look for cracks, bends, and breaks.

Airbag

The actual airbag has no abrasions, bulges, cuts, or leaks. The airbag is not missing mounting bolts.

Axle Seal

The axle seal is not leaking and is filled to the manufacturer’s specifications.

Brake Chamber

The brake chamber is not leaking air.

Brake Drum

The brake drum is secured properly and has no cracks, bends or breaks.

Brake Hose

Check the brake hose at both ends to make sure it is not leaking air.

Brake Lining

There is no oil or debris on the brake lining. There is at least ¼ of an inch of friction material.

Catwalk and Steps

The cat walk and steps are clear of any loose objects.

Door and Hinges

The doors open, close, and latch properly. Door seals should not be worn, torn, or rotten.

Drive Shaft

The drive shaft is not twisted, and the u-joints are free of any debris.

Drive Tire

The tread and sidewalls have no abrasions, bulges, or cuts. The tread depth is no less than 2/32 of an inch. Tires are properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

Exhaust System

The exhaust system shows no signs of leaks.

Frame and Cross Members

There are no unauthorized holes or welds. Bundle up the cross members to ensure none are missing.

Fuel Tank

Fuel is not leaking from the tank, and the cap is on tight.

Lug Nuts

There are no rust trails, loose bolts, powder residue, or cracks around the bolts.

Mirrors

Mirrors are clean, with no cracks or chips.

Mud Flap

The mud flap is secured properly, with no cracks, bends and breaks.

Rim

There are no unauthorized welds.

Shock Absorber

The shock absorber is secure at both ends and not leaking. If it does leak, it is preferable to leak in the middle.

Slack Adjuster and Push Rod

With the brakes released and pulled by hand, the push rod does not move more than one inch.

Spacing

There is proper spacing between the tires and there is nothing stuck.

Spring Arm

The spring arm is secure at both ends.

Spring Mount

The spring mount is secure at both ends.

Torque Arm

The torque arm is secured properly, with no cracks, bends or breaks.

U-Bolts

No u-bolts are missing.

Coupling Area-What to Check For:

Air Lines

Air lines should be secure at both ends with no abrasions, bulges, or cuts. They should not be leaking, dragging, or tangled.

Apron

Make sure the apron is properly mounted and secure. Look for cracks, bends, and breaks.

Clearance

Make sure there is enough space between the tractor mud flap and the trailer landing gear, so that they don’t hit each other when making a turn.

Electric Line

The electric lines are secure at both ends. There are no abrasions, bulges, cuts, or exposed wires.

Gap

There is no space between the apron and the skid plate.

Glad Hands

The seals are in good condition with no cracks, signs of rotting, or leaking air.

King Pin

The king pin is properly mounted and secure, without cracks, bends and breaks.

Locking Jaws

Physically check that the locking jaws are fully locked around the king pin.

Mounting Bolts

No mounting bolts are missing.

Platform

The platform is properly mounted and secure, without cracks, bends and breaks.

Release Arm

The release arm is in the fully locked position.

Skid Plate

The skid plate is properly lubed.

Sliding Fifth Wheel Locking Pin

The pin is in the fully locked position.

Trailer- What to Check For:

Airbag

The airbag has no abrasions, bulges, cuts or leaks, not missing any mounting bolts.

Axle Seal

The axle seal is not leaking and is filled to the manufacturer’s specifications.

Brake Chamber

The brake chamber is properly mounted and does not leak air.

Brake Drum

The brake drum is properly mounted and secure.

Brake Hose

The brake hose is secure at both ends with no abrasions, bulges, cuts, or leaks.

Brake Lining

No oil or debris on the brake lining and at least ¼ of an inch of friction material.

Frame and Cross Members

No missing cross members.

Header Board

The header board does not have any holes or missing rivets.

Landing Gear

The landing gear is fully raised and the cradle handle secure.

Lug Nuts

No rust trails, powder residue, or cracks around the bolt holes.

Rim

The rims do not have any unauthorized welds.

Rear Door and Hinges

The rear door opens, closes, and latches properly. Door seals are not worn, torn, or dry rotten.

Shock Absorber

The shock absorber is secure at both ends with no leaks.

Slack Adjuster and Push Rod

When the brakes are released and pulled by hand, the push rod does not move more than one inch.

Tandem Frame and Release

Release handle and locking pins are in the fully locked position.

Trailer Tire

There are no abrasions, bulges, or cuts to the tread or sidewalls. Tread depth is no less than 2/32 of an inch. The tire is properly filled to manufacturer’s specifications and checked with an air gauge.

Light Check

There are five locations where you must check your lights. These include:

- Front of the truck

- Both sides of the truck

- Rear of the truck

- Both sides of the trailer

- Rear of the trailer

The five functions are:

- Left turn signal

- Right turn signal

- Four way flashers

- High/low beams

- Brake lights

Inspection and Brake Tests-What to Check For: In-Cab

The last section is In-Cab Inspection and Brake Tests. For the In-Cab Inspection you once again want to make sure all of the following components are properly mounted and secure. As well as the following:

Air Brake Test

There are three stages to an air brake test:

- Applied Pressure Test – When doing the Applied Pressure Test, you want to build the air pressure to governor cut out. Put the truck in the lowest gear, turn the engine off and immediately turn it back on. Push in the tractor and trailer valves which then release the parking brakes. Push and hold the brake pedal, allowing the gauges to stabilize. When the gauges have stabilized, announce the Primary and Secondary PSI. Listen for air leaks while doing this.

- Warning Light and Buzzer – Pump down on the brake pedal until the warning light and buzzer comes on. This is typically at or before 60 PSI.

- Tractor/Trailer Protection Valve Pop Out – Pump down on the brake pedal until the tractor and trailer protection valves pop out, this will be between 20 and 40 PSI.

Air Pressure Gauges

The air pressure gauges build to governor cut out.

Emergency Equipment

Truck has a fire extinguisher, three red reflective triangles, and spare electrical fuses.

Heater and Defroster

Demonstrate both the heater and defroster are working properly.

Horns (Air Horn and City Horn)

Blow both horns to make sure they are working.

Lighting Indicators

Check the left turn, right turn, four way flashers and high beams; also point these out on the dashboard.

Safe Start

With the transmission in neutral, fully depress the clutch. Turn the key on, check the ABS light, announce when it comes on and off, and start the engine.

Seat Belt

The seat belt is not ripped or frayed and adjusts and latches properly.

Oil Pressure Gauge

The engine oil pressure gauge should rise to normal operating range.

Parking Brake

- Trailer Parking Brakes – Set the trailer brake, release the tractor brake, and tug lightly on the trailer.

- Tractor Parking Brakes – Set the tractor brake, release the trailer brake, and tug lightly on the trailer.

Service Brake Check

Release both the tractor and trailer brakes. Drive at idle speed. Apply the service brake to make sure you come to a complete stop and that it doesn’t pull to the left or right when applying the brakes.

Voltmeter

The voltmeter is charging between 13 and 14 volts.

Water Temperature Gauge

The water temperature gauge rises to normal operating range.

Windshield and Mirrors

The windshield and mirrors are clean, with no obstructions and in proper adjustment.

Windshield Wipers and Washers

Demonstrate the wipers and washers are working properly by spraying the windshield.

This is a really nice complete list, very useful.